Silent Features

·

Heavy Structure for less vibrations.

·

Heavy duty Caster wheels for

easy movement of machine.

·

Additional wastage box to keep

wastage in one place.

·

Top side cooling fan to remove

heat from inside the machine.

·

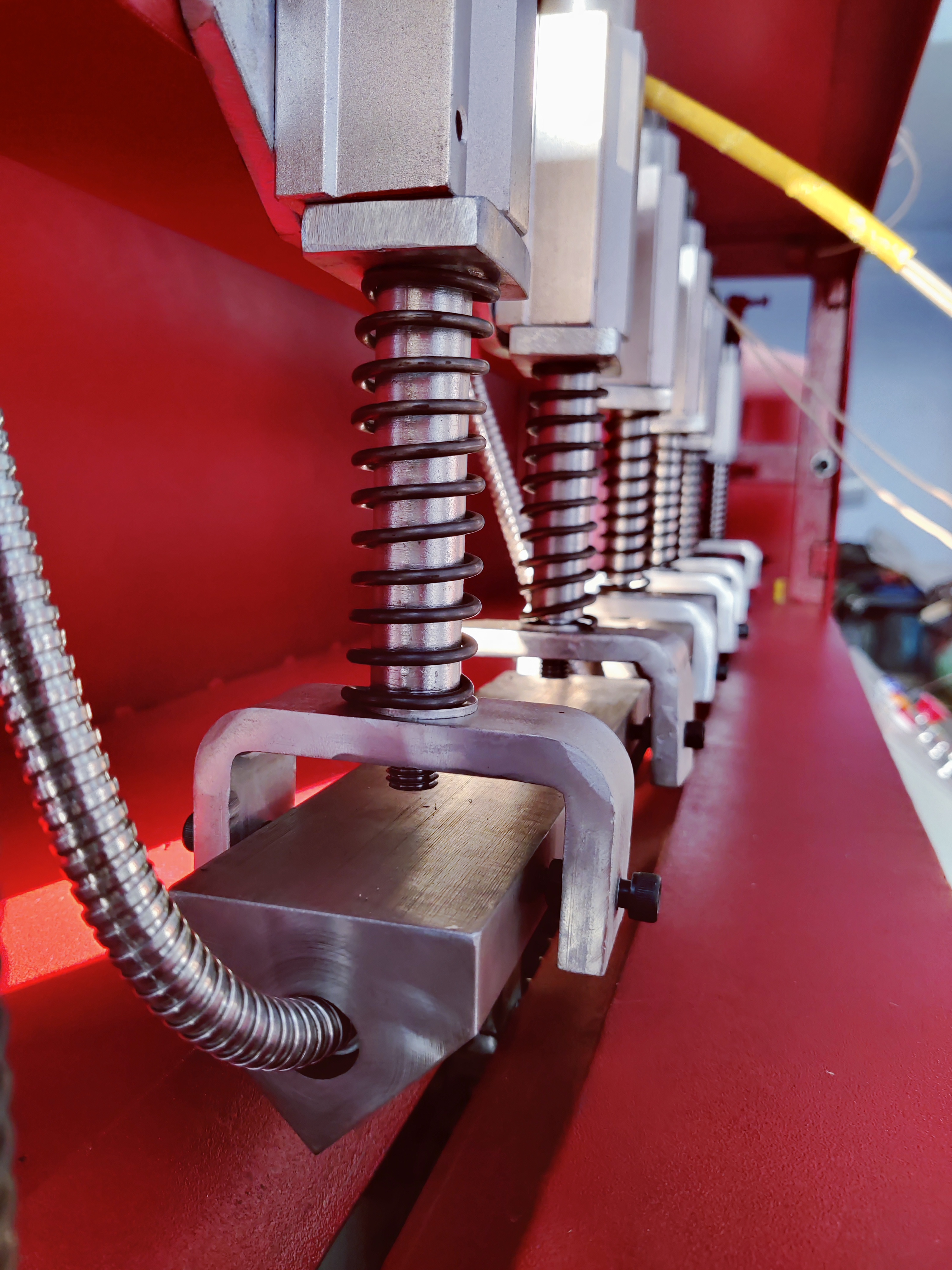

UU Type Linear bearings and Hard Chrome rods for easy linear motion of

heating blades.

·

Massive

heater blades to store more heat for a long time.

·

High

Temperature will be achieving by Pencil Heaters.

·

Speed

of machine can be change through potentiometer.

·

Front

side Acrylic glass door to prevent accidents.

·

Proper

Guide for chain conveyor with combination of Chain and Sprockets.

·

Speed

Reduction and high torque is achieving by Inline Helical Gearbox

·

Storage

Box for Pipe Storage.

•

This

machine:

•

Reducing of man power working

•

Reduction of Cutting time

•

Perfect wastage Handling

•

Improve quality of end

product